- Stock: In Stock

- Cashback: $1,079.90

- Model: FD2096

- Weight: 450.00lb

- SKU: FD2096

Available Options

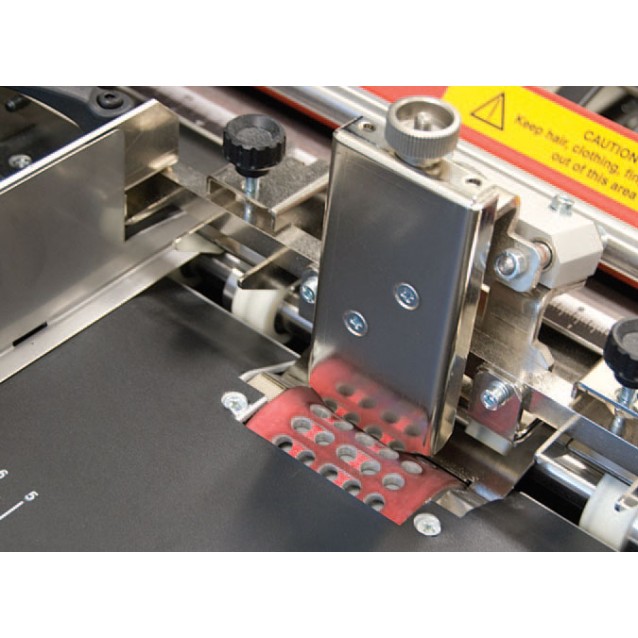

Secure Processing of One-Piece Mailers

The AutoSeal® FD 2096 uses patented pressure seal technology to efficiently process cut-sheet pressure seal forms in a mid-volume production environment, at speeds of up to 30,000 forms per hour. Its bottom-suction air-feed system provides accurate feeding and allows for continual loading of forms, dramatically reducing down time.

Set-up is quick and easy with rugged metal fold pates, clearly marked with both standard and metric markings, and fold rollers made of heavy-duty polyurethane foam, which eliminates the need for gap adjustments. The sealing unit utilizes an adjustable 17” ball transport deck for a smooth, reliable transition from the fold rollers into the sealer.

User-friendly features include sound-dampening fold plate covers for quieter operation, a 6-digit resettable LED counter, rugged locking casters, and a high-capacity 24” output conveyor which is collapsible for convenient storage when not in use.

Heavy duty construction combines with quick set-up and operation to make the FD 2096 a powerful solution for processing mid-volume pressure-seal mailings.

Operating Features

- Variable Speed: Large jobs are processed quickly at speeds of up to 30,000 forms per hour

- Top-Loading Bottom Air Feed: The air feed deck accurately feeds forms, while allowing for continuous top feeding, with no need to stop and reload

- Resettable Counter: 6-digit LED counter provides maximum audit control

- Noise Reduction: Covers and fold plates are insulated to reduce operating noise

- Rugged Construction: Designed for mid-volume production environments

- Casters for Easy Transport

Folding Features

- Heavy Duty Fold Rollers: Polyurethane foam rollers eliminate the need for gap ajustments

- Rugged Fold Plates: Metal fold plates feature metric and standard scales for easy fold setting

- Air-Feed Pump: Fully enclosed

- Rotating Air Suction Drum: Located on the feed table, separates sheets for accurate feeding

- User-Friendly Adjustments: Fold plates feature a 7-point quick-release fold stop, skew adjusment and fine tuning knob

Sealing Features

- Pressure Rollers: Precision ground clutching four-roller system

- Ball Transport Deck: Adjustable 17” ball-deck provides smooth, efficient transport from the folder into the sealer

- Fault Detection: Infrared sensor located at the infeed of the sealer detects any faults and sends a signal to stop the folding unit

- Plexi-Cover: Hinged with a handle to allow quick access to the sealing area. Includes safety interlock to stop the system when opened.

- Static Eliminator Brush: Located on the exit of the sealer to reduce static electricity and assist in the neat, sequential stacking of forms onto the conveyor

Conveyor Features

- 24” Outfeed Conveyor: Includes speed control and run-out switch for easy unloading of processed forms

- Adjustable Stacking Wheels: Help to keep processed forms in a neat, sequential order

Specifications

- Hopper Capacity: Up to 350 Sheets 24# (90gsm)

- Variable Speed: Up to 30,000 forms per hour

- Paper Size: Up to 12” W x 17” L (305mm W x 432mm L)

- Usage: Mid-Volume Production

- Power: 120V 60Hz, 30 Amp, single phase

NEMA L5-30P plug included - Dimensions (Conveyor Extended): 86” L x 28” W x 42” H (218cm L x 71cm W x 107cm H)

- Dimensions (Conveyor Closed): 64” L x 28” W x 42” H (163cm L x 71cm W x 107cm H)

- Weight: Approx. 450 lbs (205 kg)

Available Options

- 402 Series Jogger: Reduces static electricity and aligns forms for proper feeding

- Center Slitter: For applications including 2-up postcards

- V-STACK36 Vertical Stacker: Aligns with the outfeed and vertically stacks up to 22” of folded documents, making them easier to unload for further processing

| File name | Size | Action |